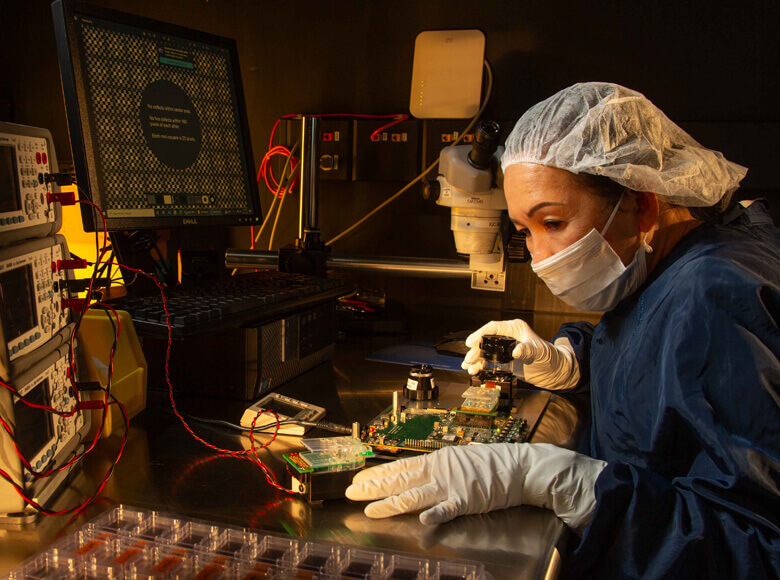

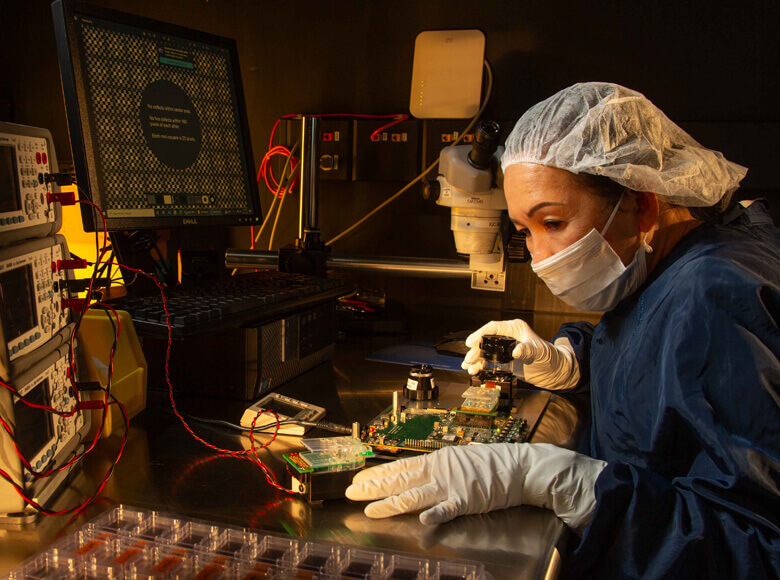

Rigorous Testing and QA

Kopin Brings Clarity to Any Challenge

Our custom testing profiles ensure we meet your specifications and requirements.

Let’s Talk

Our custom testing profiles ensure we meet your specifications and requirements.

Let’s Talk